Recyclability and Sustainability

A new generation of sustainable and recyclable films and vacuum pouches

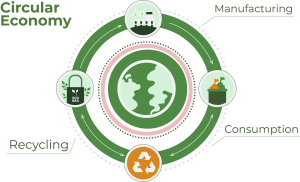

Combining 11-layer coextrusion technology with the new formulation based on Mono PolyOlefin(MPO) made of polyethyleneand polypropylene, Next Flex contributes to sustainability and meets the requirements of the regulations in terms of packaging. Thanks to the high-performance raw materials, the products have a maximum of flexibility, high barrier capacity and guarantees savings due to less weight and lower recycling fees –the optimal solution for a functional circular economy.

Markets and applications

Our line of recyclable MPO products:

- Forming and non-forming films for MAP sliced products -thermoforming applications.

- Forming film for vacuum applications such as cheese strings -substituting multilayer PA structure

- Forming/ Non-Froming for vacuum applications such as sausages and cheese -substitutes multilayer PA structures.

Polyolefin-based solutions are accepted as one of the most promising alternatives to meet future recyclability requirements. What makes polyolefins attractive for recycling is that they have low densities — allowing them to float in water — and excellent chemical resistance that is very important for mechanical recycling.

During the recycling process polyolefins keep their mechanical, functional and barrier properties intact. This is a big advantage for polyolefins and allows them to be reused.

Polyethylene and polypropylene are part of the polyolefin family.

We have the following polyolefin-based films that are recyclable (* where available):

- Clear lidding

- Flow wrapping

- Forming and non-forming

- High barrier shrink drum

- Modified atmosphere packaging (MAP)

- Multi-peel (reclosable)

- Peelable